A small investment on probiotics results in lower cost of production

Ideal water quality parameters in a bioremediation pond

The use of probiotics is one of the most important developments for sustainable shrimp farming. Probiotics are safe, effective and eco-friendly and act by stimulating shrimp growth and general health by competitive exclusion of pathogenic bacteria.

Benefits of bioremediation

Microorganisms are very imporiant and have critical roles in a shrimp culture cycle. At pre-grow out and growout stages in earthen or lined ponds, water qualily and disease prevention are directly related and closely affected by microbial activity. Microbial populations play very important roles in shrimp ponds, including the recycling of nutrients, maintaining primary productiviy and the regulation and remediation of water, pond bottom quality and also working efficiently on sludge area (Jasmin et al., 2020).

A probiotic is defined as a live microbial adjunct which has beneficial effects on the host by modifying he host- associated or ambient microbial communilty. Probiofics act by ensuring improved use of the feed by enhancing its nutritional value, as well as enhancing the host response towards disease or by improving the quality of its ambient environment (Verschuere et al., 2000).

Water and soil probiotics are regularly applied in shrimp ponds to modify as well as manipulate the microbial communities in the water column and pond bottom sediments. This is either to reduce or eliminate specific pathogenic species of microorganisms (Vibrio parahaemolyticus and Vibrio harveyi) and therefore improve shrimp survival rales (Toledo et al., 2019). Verschuere et al., (2000) said that most probiotics proposed as biological conttrol agents in aquaculture belong to the laclic acid bacteria (Laclobacillus, Carnobacterium, etc.) or to the genus Vibrio (Vibrio alginolyticus, etc.), Bacillus or Pseudomonas as well as other genera or species.

Bioremediafion plays a major role in making available a supply of natural food, as well as enhancing mineral recycling rates and dissolved oxygen dynamics in shrimp ponds. It also helps in competitive exclusion of pathogenic bacterial population and improves the general health of shrimp throughout the crop cycle.

In this article, we show that bioremediation provides significant benefits with a potential to improve shrimp yields and minimise cost of production. For the past three years, we conducted trials at the R&D farm of Growel Feeds Pvt Ltd, Andhra Pradesh and in customers farms across India. These bioremediation protocols have been part of Growel’s SOP, leading to crop success rates of more than 90%. To show crop production economics between treatment and control ponds, we used recent data from July 2022 to March 2023.

Lower cost of production

Production costs in ponds with bioremediation protocols are typically lower. Improvements in yields increase the overall profitability. Bioremediation is most cost effective compared to other producltion management procedures.

Bioremediation simply relies on the regular addition of simple, highly digestible carbohydrates (such as molasses, jaggery and rice bran) on which heterotrophic bacteria can thrive. This carbon addition, together with nitrogen wastes from shrimp feed will enhance a bacterial bloom which consumes NH4+ for the synthesis of bacterial proteins, thus leaving less room for photosynthesis in the pond which then results in more stable water quality.

Bioremediation technology (aerobic and anaerobic fermentation) already provides significant benefits to shrimp farmers around the world. Such a system is supposed to ensure more stable dissolved oxygen (DO) levels between day- and night- time and to avoid algal crashes which are associated with low DO and poor water quality events (Ebeling et al., 2006; Samocha et al., 2007). Furthermore, dense bacterial populalion is suspected to have a controlling effect over pathogenic bacteria for shrimp, such as V. parahaemolyticus (Crab et al., 2007).

Importance of bioremediation

After disinfection of pond water, Vibrio can quickly re-establish itself in the culture water. With this pace of Vibrio growth, water and soil probiotics after fermentafion (called bacterial amendments) through bioremedialtion protocols can compete with Vibrio for competitive exclusion in shrimp ponds. Two to three applications of probiotics per week after fermentation will suffice.

Beneficial bacteria can be activated by fermenting small amounts of probioic powder at 200 to 300g/ha every 3 days from 10 days prior to stocking, in sterile and near zero salinity water wiih constant aeration and sterile organic carbon sources. Once after the maturation of pond water is completed, post larvae can be stocked.

Healthy shrimp harvested from bioremadiation pond.

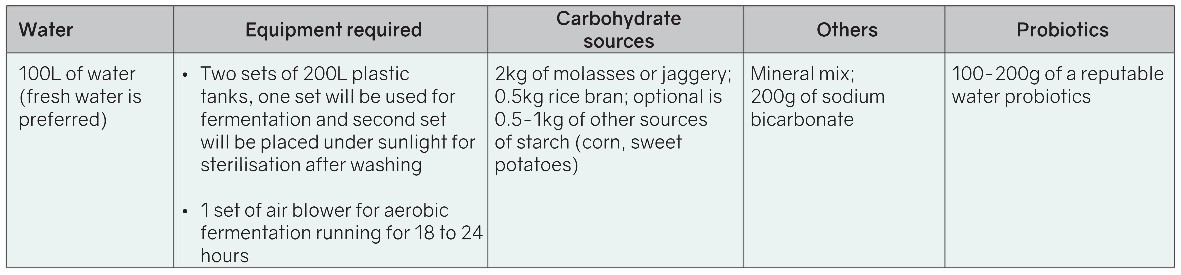

Aerobic activation

Materials and method used for aerobic activation are given in Table 1. The recommended application is 100L/ha of pond wafer once in three days and preferably at 9-10am.

Table 1: List of materials requires for aerobic activation of probiotics.

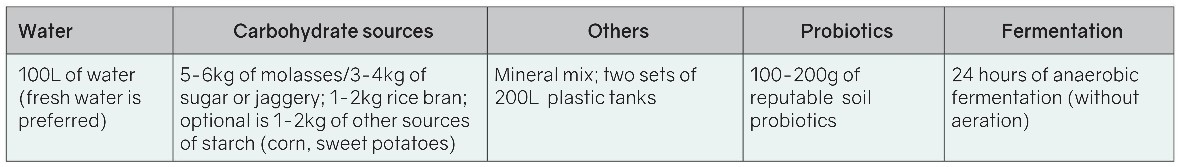

Anaerobic fermentation

Anaerobic fermentation is the metabolic process by which probiotic strains extract energy from carbohydrates in the absence of oxygen to multiply and produce various bioactive metabolites. The list of materials required is given in Table 2. The recommended application is at 100L/ha daily and preferably carried out at 2-3 am. During pond preparation, the application is at 500L/ha to enrich pond bottom soil.

Table 2: List of materials required for anaerobic fermentation of probiotics.

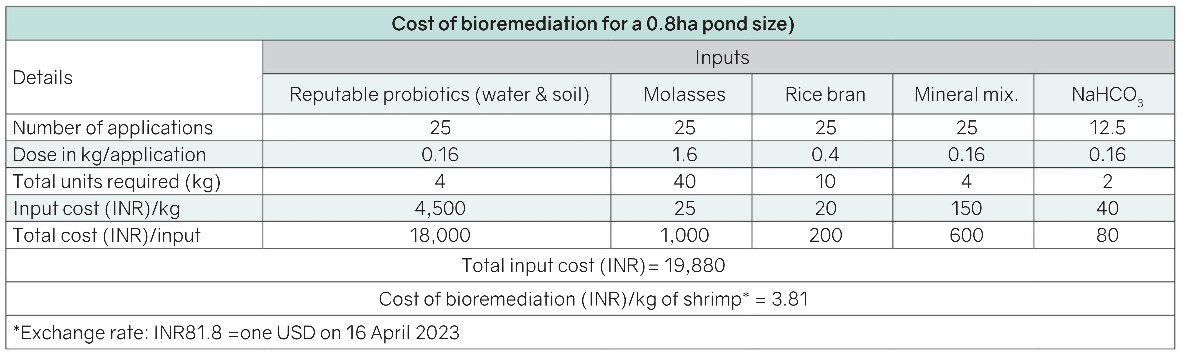

The general observations from these pond trials are that bioremediation plays a vital role in vannamei shrimp growth, survival rate and disease resistance by maintaining beneficial bacterial population and competitive exclusion of pathogenic bacteria in shrimp ponds throughout the crop cycle. In these trials we have shown that with the use of pond probiotics, at an additional cost of INR3.81 (USD0.05) per kg of shrimp, gave improvement in yields.

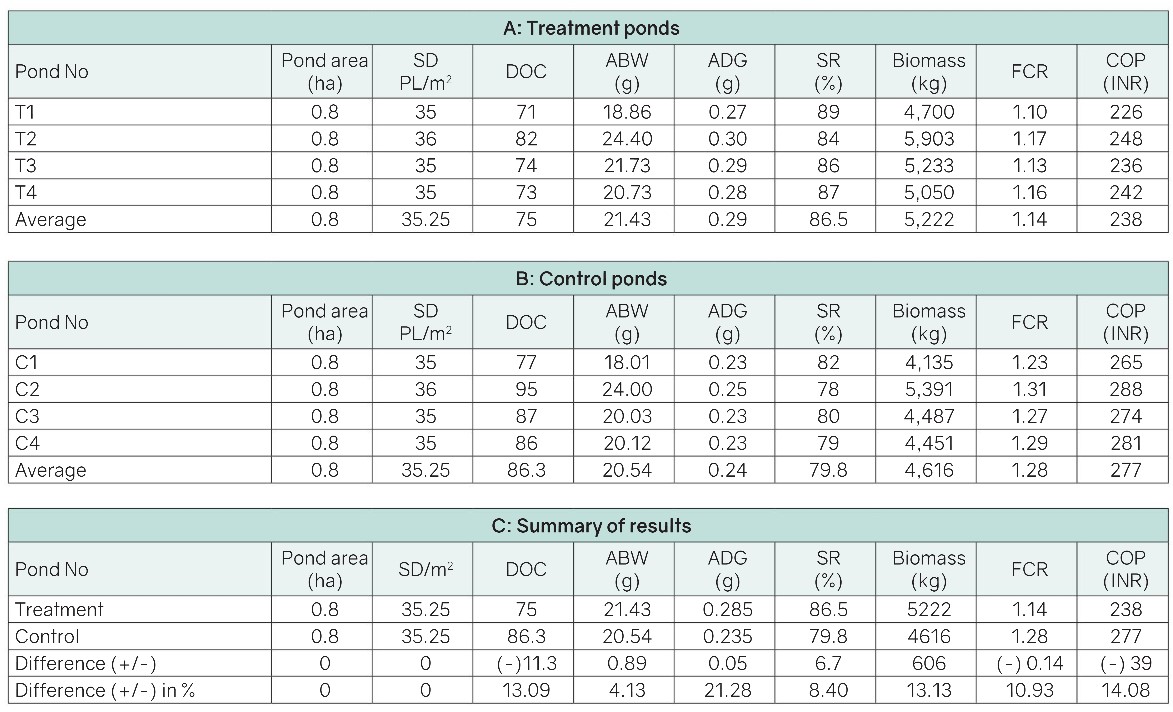

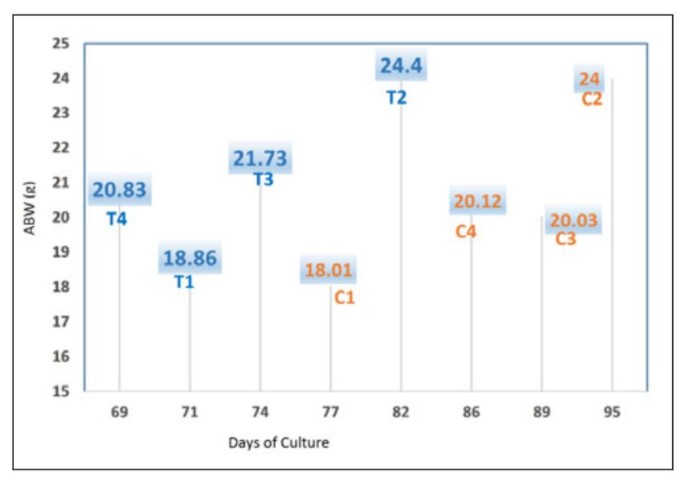

The average daily growth (ADG) of the harvest shrimp was 0.28g and 0.23g in bioremediation and control ponds, respectively. The difference was significant between two production systems. ADG was 18% higher in bioremediation ponds than in the control pond whereas shrimp production was 13.13% higher in bioremediation than control ponds (Tables 3 and 4 and Figure 4).

Table 3: Cost of inputs for bioremediation in shrimp farming. The total cost was INR3.81/kg of shrimp.

Table 4: Results from trials at the Growel R&D Farm as well as 27 customers farms across India conducted from July 2022 to March 2023. SD=stocking density; DOC= days of culture; ABW= average body weight; ADG= average daily growth; SR= survival rate; FCR= feed conversion ratio; COP= cost of production. A: treatment ponds; B: control ponds and C: Summary of results with % differences.

Figure 3: Growth performance of vannamei shrimp as average body weight (ABW in g) in treatment ponds T1 – T4 (blue) and control ponds C1- C4 (orange). In treatment ponds, the ABW was 21.43g at DOC 75 due to better shrimp growth than in control ponds, where ABW was 20.54g at DOC 86. As most of the farmers prefer to harvest between 20 to 25g due to better farm gate prices and to get more crops per year, the crops in the treatment ponds were harvested earlier.

The average feed conversion ratio (FCR) and cost of production (COP) were lower in treatment ponds (1.14 and INR238/kg or USD 2.90/kg, respectively) compared to control ponds (1.28 and INR277/kg or USD3.38/kg, respectively). The average survival rate in treatment ponds was 8.4% higher than the control ponds due to good shrimp health condition throughout the crop cycle (Table 4).

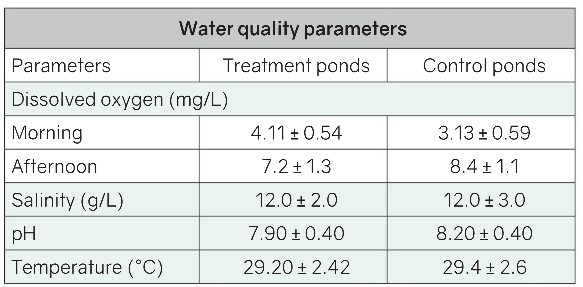

Additionally, we observed that daily variation of water quality parameters (dissolved oxygen and pH) was minimal in treatment ponds. This reduced the stress levels for the shrimp (Table 5).

Table 5: Summary of water quality parameters during the trials.

By B. Ravikumar, Loc Tran, Gnana Sri, Uma Maheswararao and Ramesh Arji

Reference: https://issuu.com/aquacultureasiapacific/docs/aq23187_aap_may_jun_23_fa_mr?e=28637981/97054108

DOMESTICATED SHRIMP POSTLARVAE – THE KEY TO SUCCESS

See more:

- Aqua-Spark backs Vietnamese shrimp tech business

- Shrimp market Update: facing new challenges

- Ecuador hosts global shrimp buyers for second shrimp summit

Tiếng Việt

Tiếng Việt 中文 (中国)

中文 (中国)